Multifunctionality Vertical Lifting Fermentation Machine

Vertical Lifting Fermentation Tower

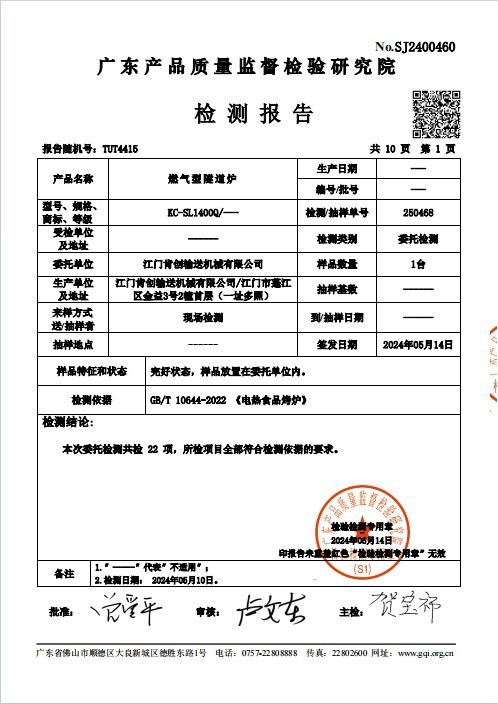

-

+86-13427473518 WhatsApp

-

kc001@jm-kc.com Email

Multifunctionality Vertical Lifting Fermentation Machine: A new generation of complete equipment that introduces advanced technology from similar foreign models and combines domestic baking product characteristics. It features small footprint, relatively low cost, stable conveyance, and effectively eliminates the adverse effects of baking pan jumping on dough fermentation. The temperature and humidity in the fermentation room are adjusted through air supply and return systems to achieve the optimal environment for dough fermentation. Multiple sensors are installed in the fermentation room to monitor changes in various data throughout the process and automatically make adjustments. The height, length, width, and height of the tower can be customized according to customer product and production capacity requirements. As a China vertical lifting fermentation machine manufacturer, KC-SMART focused on the customized design, manufacturing, installation, debugging, and after-sales maintenance of intelligent mechanical equipment.

Control System:

Controlled by PLC and with parameter settings made on the touch screen, the system can adjust the conveying speed of the fermentation tower, as well as the temperature and humidity inside the fermentation chamber, to meet the fermentation requirements of various products, as different products have different fermentation time, temperature, and humidity requirements. Additionally, it is equipped with fault shutdown protection functions such as chuck, overload, and emergency stop.

Multifunctionality Vertical Lifting Fermentation Machine Specifications

| Product Name | Vertical Lifting Fermentation Tower | |||

| Model | KCSF-01 | KCSF-02 | KCSF-03 | KCSF-04 |

| Voltage | 380V3N | 380V3N | 380V3N | 380V3N |

| Power | 6kW | 8kW | 10kW | 12kW |

| Ovenware Size | 400*600 | 400*600 | 400*600 | 400*600 |

| OEM/ODM | Accept | |||

| Compay Nature | China Manufacturers Suppliers Factory | |||

Multifunctionality Vertical Lifting Fermentation Machine Advantage

One of our standout products is the customized vertical lifting fermentation machine, engineered to optimize fermentation processes in large-scale baking environments.

1. Vertical fermentation tower with efficient space utilization

The vertical fermentation tower is made of 304 stainless steel, which is durable and corrosion-resistant. Its unique design allows up to 12 layers of trays to move up and down at the same time, greatly improving production efficiency. This structure achieves maximum production capacity in a limited vertical space, which is an ideal choice for production sites with limited space. It can achieve efficient fermentation operation without occupying too much floor area to meet the needs of large-scale production.

2. Versatility and precise control

The fermentation tower is versatile and can meet the fermentation needs of different types of products. Its precise temperature and humidity control system is one of its core advantages. Through advanced sensors and control technology, the fermentation tower can accurately adjust the internal temperature and humidity according to different fermentation process requirements to ensure that the fermentation process is carried out under optimal conditions. This precise control capability enables the fermentation tower to adapt to various complex fermentation environments, whether it is temperature-sensitive microbial fermentation or food fermentation with strict humidity requirements, it can easily cope with it, thereby ensuring the quality and consistency of the fermented products.

3. Perfect combination of manual and automatic operation

The fermentation tower combines manual and automatic operation modes to provide users with flexible operation options. In manual mode, operators can make fine adjustments according to actual needs, which is convenient for direct control of the equipment during the debugging stage or special circumstances. In automatic mode, the equipment can run stably according to the preset program, reducing human operation errors and improving the stability and reliability of production. This dual operation mode not only ensures the convenience of operation, but also realizes the silent operation of the equipment, reduces noise pollution, and the high stability and low failure rate of the equipment also reduce maintenance costs and downtime, ensuring the continuity of production.

4. Intelligent full-automatic control

The fermentation tower is equipped with a fully automatic intelligent control system and an intuitive touch screen operation interface. Through the touch screen, operators can easily set and monitor the operating parameters of the equipment, such as temperature, humidity, fermentation time, etc. This intelligent control method not only simplifies the operation process, but also improves production efficiency. The equipment can automatically complete various operations in the fermentation process, reducing manual intervention and labor intensity. At the same time, its energy-saving design reduces energy consumption while ensuring production efficiency, which is in line with the concept of modern green production. Whether it is batch production or continuous production, the fermentation tower can meet production needs in an efficient and energy-saving manner, bringing convenience and benefits to users.

5. Full automation and integrated operation

The fermentation process of the fermentation tower is highly automated, without the need for midway shutdown or manual intervention. The system can monitor various parameters in the fermentation process in real time and automatically adjust to ensure the smooth progress of the fermentation process. This integrated operation mode makes the operation of the entire conveyor tower more coordinated and consistent. From the delivery of raw materials to the output of finished products, the entire process can be completed automatically without human supervision. This not only greatly reduces manpower input, but also saves time and improves production efficiency. For modern enterprises pursuing efficient and automated production, this fully automated and integrated fermentation tower is an ideal choice, which can significantly improve the production competitiveness and economic benefits of the enterprise.

Multifunctionality Vertical Lifting Fermentation Machine FAQ

Q: What is the difference between a vertical lifting fermentation machine and a traditional fermentation machine?

A: convenient for discharging. The dough quality is stable with a cooling jacket. The surface temperature is controllable. It has stable operation and long service life.

Q: Is the vertical lifting fermentation machine easy to operate?

A: It have PLC control system, which is equipped with a display screen human-machine interface to achieve recipe management and more flexible and convenient daily operations.

Q: Is the vertical lifting fermentation machine easy to clean?

A: The all-stainless steel body and open structure design are easy to clean and maintain.

Q: Does the horizontal mixer have internal leakage of pollutants?

A: The unique shaft seal design avoids the risk of internal leakage of contaminants.

Q: Which foods are suitable for vertical lifting fermentation machine?

A: Hamburgers, toast, European-style panels, pizza, Mexican crusts, Chinese pastries, frozen dough, etc.

Q: What are the types of vertical lifting fermentation machine?

A: 4 types. The production capacity is 150kg-450kg.

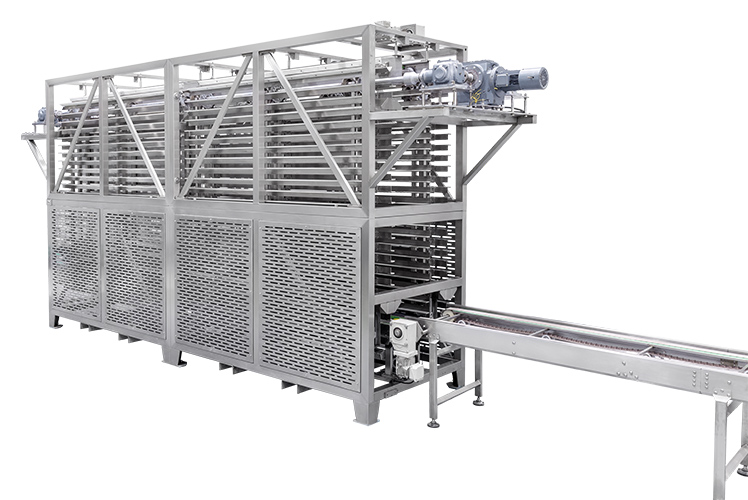

Production Environment

With advanced equipment and skilled personnel, we provide customized design, manufacturing, installation, debugging, and after-sales maintenance of intelligent mechanical equipment.

Engineering Cases

We deeply understand that every customer has diverse needs. Therefore, we provide professional customized baking solution services, tailoring baking engineering machines according to customers' actual requirements. From the functional configuration to the design of the machine, we fully consider customers' personalized needs to ensure that every machine becomes a proud product for the customer.

Application Scenarios

KC-SMART provides cutting-edge solutions tailored to the baking industry. Our intelligent mechanical equipment is widely used in the production of diverse baked goods, including bread, mooncakes, cookies, and cakes.

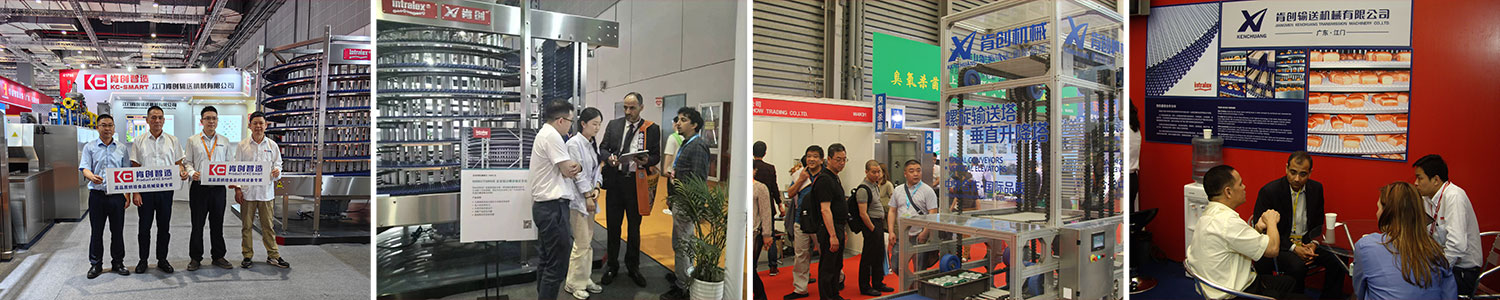

Exhibitions

At KC-SMART, we actively participate in industry-leading trade shows to showcase our advanced intelligent mechanical equipment for the global baking industry. These exhibitions provide an excellent platform to connect with clients, discuss their specific needs, and demonstrate our solutions for powder transportation, mixing, fermentation, baking, cooling, and material handling.

KC-SMART founded in 2000, is a high-tech enterprise dedicated to providing global baking food customers with one-stop solutions, including customized design, manufacturing, installation, debugging, and after-sales maintenance of intelligent mechanical equipment. Guided by the values of "willingness to work hard and innovate, and win-win future" and the business philosophy of "honesty, quality, responsibility, and respect for talents," the company strives to deliver the best possible service.

Located at No. 3 Jinyi Road, Pengjiang District, jiangmen City, Guangdong Province, the company covers an area of over 10,000 square meters. Its product line includes intelligent mechanical equipment for powder transportation, mixing, fermentation, baking, cooling, demolding, and material handling, among others. The company also holds multiple practical invention patents.

Looking ahead, Jiangmen Kenchuang Conveying Machinery Co, Ltd. will continue to uphold the spirit of innovation, constantly improve product quality and service levels, and provide even more intelligent and efficient mechanical equipment solutions for global baking food customers. Together, we aim to create a brighter future for all.